Installation Instructions

- Categories:客户服务

- Time of issue:2021-01-11 13:43:31

- Views:0

Ⅰ.Mechanical seals Installation

1.Check whether the model and specification of the mechanical seal installed are correct.

2.Check whether the dimensional tolerance, geometric tolerance and surface roughness of the relevant parts of the main engine installationmeet the technical requirements.

lt mainly includes the following aspects:

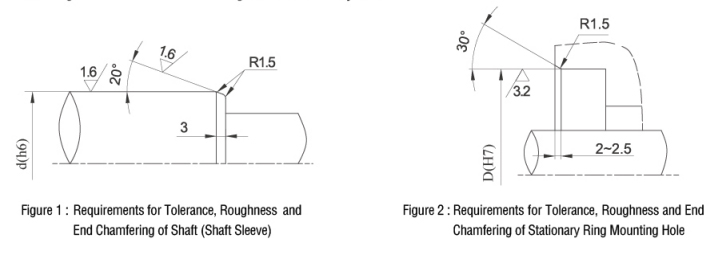

(1).The radial runout tolerance of shaft (or shaft sleeve) installed with mechanical seal shal not be greater than 0.06mm, surface roughnessand outer diameter dimension tolerance of shaft (or shaft sleeve).

(2).The chamfering , roughness and dimensional tolerance of shaft(or sleeve) end of primary ring and mating ring hole of mechanical seal shalmeet the requirements of Fig. 1 and Fig. 2.

(3).The axial displacement of the shaft(or shaft sleeve) installed with mechanical sal shall not exceed 0.3mm, and that of multistage pumpshall not exceed 2mm.

3.During the installation of mechanical seal, keep it clean and do not knock the sealing parts, otherwise the sealing ring will be deformed or theceramic sealing ring will be damaged.

4.Before the instllation of auxiliary seal ring (dynamic o-ring and static o-ring), clean silicone oil shall be applied as lubricant to ensure smothinstallation. Ethylene propylene rubber shall not contact with mineral oil.

5.Dry the sealing surfaces of dynamic and static rings with degreasing gauze, and drop 3-4 drops of clean engine ail or turbine ail on the sealingsurfaces.

6.The mechanical seal rotary part is fixed by the set screw on the spring seat and the shart. When tightening the set screw,the working lengthof the seal rotary units should be ensured.

7.When installing the sealing gland, tighten the screws evenly to ensure that the end face of the stationary ring is perpendicular to the axis line.8.After installation, rotate the shaft by hand to check whether the shaft can rotate easily f the rotation is heavy,.check whether the instlationdimension is correct.

Ⅱ. Mechanical Seals Operation

1.When the medium temperature is higher than 80°C, coesponding flushing, fitering and cooling measures shall be taken for easy crystal-lization and particle media. Various auxiliary devices shall refer to relevant standards of mechanical seal.

2.Before starting the main engine, check whether the aurillary device of mechanical seal and cooling and lubrication system are perfect and unblocked.3.Before starting the main engine, the sealing chamber should be filled with medium. If there is a separate sealing system, it should be started5~10 minutes in advance. The cooling system should also be started 5-10 minutes in advance.

4.Prior to normal operation,run under normal pressure first, and observe whether the temperature rise of the sealing part is normal and wheth-er there is leakage. If there is slight leakage,run in for a period of time to make the end face fit more evenly until the leakage is gradually reducedto normal. lf the leakage does not decrease after 1-3 hours of operation, it is necessary to stop for inspection.

5.Stop the main engine first and then the cooling and lubrication system.

Scan the QR code to read on your phone

CONTACT US

Ningbo Tiangong Fluid Technology Co.,Ltd

NINGBO PLANT-1

ADD: No.18 Gaoya Road, Jiangshan Science and Technology Zone, Yinzhou District, Ningbo

CHINA 315191

NINGBO PLANT-2

ADD: No. 65, Mingke Road, Jiangshan Town, Yinzhou District, Ningbo, Zhejiang, CHINA 315191

Domestic Business Tel.: 0574-28805518, 28805528

International Business Tel.: 0086-574-28805588, 28805516

FAX: 0086-574-28805526

E-mail: jim@tianfeng.com, tianfeng@tianfeng.com

Post Code: 315191

Copyright © 2020 Ningbo Tiangong Fluid Technology Co.,Ltd All rights reserved. 浙ICP备14001930号-1